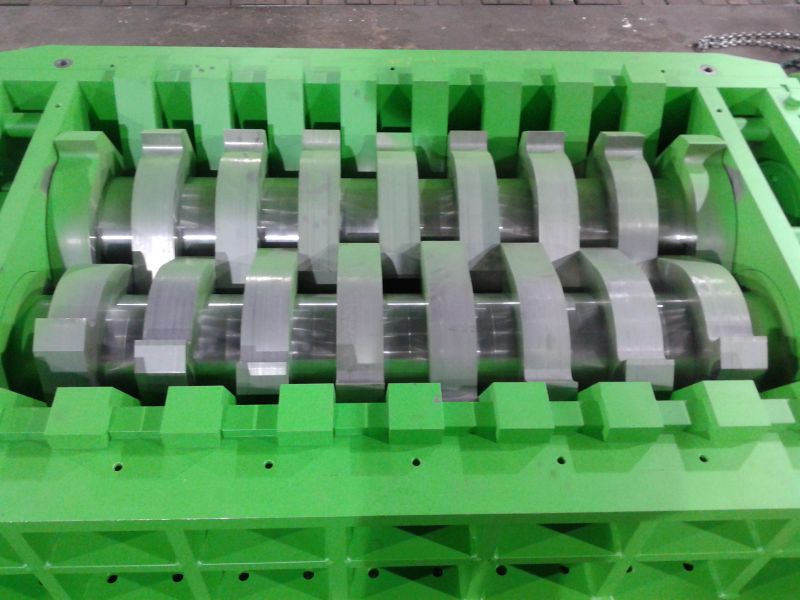

Double-shaft shredders

Double-shaft shredders cut and shred material by the segments mounted on the shafts, which slowly rotate against each other. The output from shredders are strips or pieces of waste whose size depends on the nature of the input material and the width of segments. Shredders are driven through the gearbox with one or two electric motors or hydraulic motors. Double-shaft shredders are suitable for shredding of different kinds of waste, such as; plastics, cardboard, wood, laminate, tires, etc. These machines are often used as the first machines in different lines for processing waste for pre-shredding of waste prior to the main shredding or fine grinding. Shredders can be equipped, If it’s necessary, by a hydraulic pressing device, which ensures pushing bulk material between shredding segments.

DRE series - Our smallest manufactured low-speed shredders is DRE series. A material is shredded by segments mounted on two shafts, which slowly rotate against each other. The output from shredders are strips or pieces of waste whose size depends on the nature of the input material and the width of segments. Due to the fact that these are our smallest manufactured shredders, it is necessary to take into account small force parameters of it. In order to use DRE series effectively, material must be easy to be process mechanically. The capacity is about 150-300 kg/hour when material is loaded continuously and considering the sustainability of permanent shafts rotation.

DRN and DRK series - Our middle class of low-speed shredders with one drive are DRN a DRK series. The principle of shredding is the material is cut at the edges of segments with extension rings stacked on shafts shredders. For non-adhesive, fragile and easily mechanically crushable materials may be placed a sieve below the working space to achieve a smaller and more homogenous output fractions. In general, the mesh size of the sieve cannot be smaller than the width of cutting segments. The capacity is about 500 - 1500 kg/hour.

DRT series - Our strongest manufactured low-speed shredders with one drive is DRT series. It is used for industrial pre-shredding waste materials for further processing (final shredding, combustion, transportation, etc.). Robustness, power parameters and reliability of DRT series represents fact that it is our best-selling series. The capacity is about 1500 - 2500 kg/hour.

DRE series - Our smallest manufactured low-speed shredders is DRE series. A material is shredded by segments mounted on two shafts, which slowly rotate against each other. The output from shredders are strips or pieces of waste whose size depends on the nature of the input material and the width of segments. Due to the fact that these are our smallest manufactured shredders, it is necessary to take into account small force parameters of it. In order to use DRE series effectively, material must be easy to be process mechanically. The capacity is about 150-300 kg/hour when material is loaded continuously and considering the sustainability of permanent shafts rotation.

DRN and DRK series - Our middle class of low-speed shredders with one drive are DRN a DRK series. The principle of shredding is the material is cut at the edges of segments with extension rings stacked on shafts shredders. For non-adhesive, fragile and easily mechanically crushable materials may be placed a sieve below the working space to achieve a smaller and more homogenous output fractions. In general, the mesh size of the sieve cannot be smaller than the width of cutting segments. The capacity is about 500 - 1500 kg/hour.

DRT series - Our strongest manufactured low-speed shredders with one drive is DRT series. It is used for industrial pre-shredding waste materials for further processing (final shredding, combustion, transportation, etc.). Robustness, power parameters and reliability of DRT series represents fact that it is our best-selling series. The capacity is about 1500 - 2500 kg/hour.

| Model | Type | Working area | Width of segments | Power | Weight |

| A x B | [mm] | [kW] | [kg] | ||

| DRE | DRE 350 | 350 x 320 | 12, 20 | 3 - 4 | 390 |

| DRM | DRM 280 | 280 x 330 | 10, 20 | 3 - 5,5 | 350 |

| DRM 440 | 440 x 330 | 10, 20 | 3 - 5,5 | 450 | |

| DRN | DRN 480 | 480 x 460 | 12, 18 | 7,5 - 9,5 | 1 270 |

| DRN 580 | 580 x 460 | 12, 18 | 7,5 - 9,5 | 1 380 | |

| DRK | DRK 500 | 520 x 560 | 18, 36 | 11, 15 | 1 460 |

| DRT | DRT 600 | 590 x 590 | 32, 64 | 22, 30 | 2 500 |

| DRT 730 | 730 x 590 | 32, 64 | 22, 30 | 2 760 | |

| DRT 900 | 910 x 590 | 32, 64 | 22, 30 | 3 100 | |

| DRT 1200 | 1200 x 590 | 32, 64 | 22, 30 | 3 900 |

DRD series - low-speed shredders with two drives (one for each shaft). They are designed for pre-shredding of large, bulky and tough materials with demand for a higher hourly capacity. These crushers are in most cases equipped with a hydraulic pressing device. The capacity is about 3000 - 5000 kg/hour.

DRW and DRU series - Our largest manufactured low-speed shredders with two drives, consist of two electric or hydraulic drives (-H) for each shaft. These shredders are designed as heavy-duty, to be able to process oversized waste materials. DRU are the largest stationary shredders made in the Czech Republic. They are equipped with a hydraulic pressing device for pushing bulky waste into the workspace. The capacity is from 5000, 10,000 and over kg/hour.

DRW and DRU series - Our largest manufactured low-speed shredders with two drives, consist of two electric or hydraulic drives (-H) for each shaft. These shredders are designed as heavy-duty, to be able to process oversized waste materials. DRU are the largest stationary shredders made in the Czech Republic. They are equipped with a hydraulic pressing device for pushing bulky waste into the workspace. The capacity is from 5000, 10,000 and over kg/hour.

| Model | Type | Working area | Width of segments | Power | Weight |

| A x B | [mm] | [kW] | [kg] | ||

| DRD | DRD 840 | 840 x 800 | 52, 72 | 2 x 22, 2 x 30 | 4 500 |

| DRD 1160 | 1160 x 800 | 52, 72 | 2 x 22, 2 x 30 | 5 200 | |

| DRD 1670 | 1670 x 800 | 72 | 2 x 22, 2 x 30 | 6 700 | |

| DRW | DRW 1000 | 1000 x 940 | 45, 90 | 2 x 37, 2 x 75 | 7 200 |

| DRW 1300 | 1300 x 940 | 45, 90 | 2 x 37, 2 x 75 | 8 400 | |

| DRW 1600 | 1600 x 960 | 45, 90 | 2 x 37, 2 x 75 | 9 300 | |

| DRW 2000 | 2000 x 960 | 45, 90 | 2 x 37, 2 x 75 | 11 000 | |

| DRU | DRU 2400 | 2400 x 1300 | 92 | 2 x 75, h200 | 22 000 |

KONTAKTY

DEOS Technology s.r.o.

E-mail: info@deostech.cz

Web: www.deostech.cz

Sídlo:

Rybalkova 543, 551 01 Jaroměř

Provozovna:

Dolecká 14, 551 01 Jaroměř

Ing. Alžběta Šimonová

ředitelka, tel. 731 466 621

alzbeta.simonova@deostech.cz

Ing. Petr Hynek

projektový manažer, tel. 775 779 107

petr.hynek@deostech.cz

Martin Bittner

konstruktér, tel. 604 150 461

martin.bittner@deostech.cz

Luděk Hrdlička

výrobní ředitel, tel. 730 517 278

ludek.hrdlicka@deostech.cz

Vlasta Pácaltová

účetní, tel. 604 179 696

E-mail: info@deostech.cz

Web: www.deostech.cz

Sídlo:

Rybalkova 543, 551 01 Jaroměř

Provozovna:

Dolecká 14, 551 01 Jaroměř

Ing. Alžběta Šimonová

ředitelka, tel. 731 466 621

alzbeta.simonova@deostech.cz

Ing. Petr Hynek

projektový manažer, tel. 775 779 107

petr.hynek@deostech.cz

Martin Bittner

konstruktér, tel. 604 150 461

martin.bittner@deostech.cz

Luděk Hrdlička

výrobní ředitel, tel. 730 517 278

ludek.hrdlicka@deostech.cz

Vlasta Pácaltová

účetní, tel. 604 179 696